Retroreflective

The world of optics is an interesting one. From images that play with our minds to real-world properties that look like magic.

One of those real-world applications of optical and material sciences is Retroreflective materials. Retroreflective materials are materials that reflect almost all light that they get back to the source. You might know them as road signs.

or reflectors for bicycles.

It is really impressive when in the deep dark of the night you see a bright sign standing amidst the darkness and know that it is unpowered, every single photon that you see coming from it came from you.

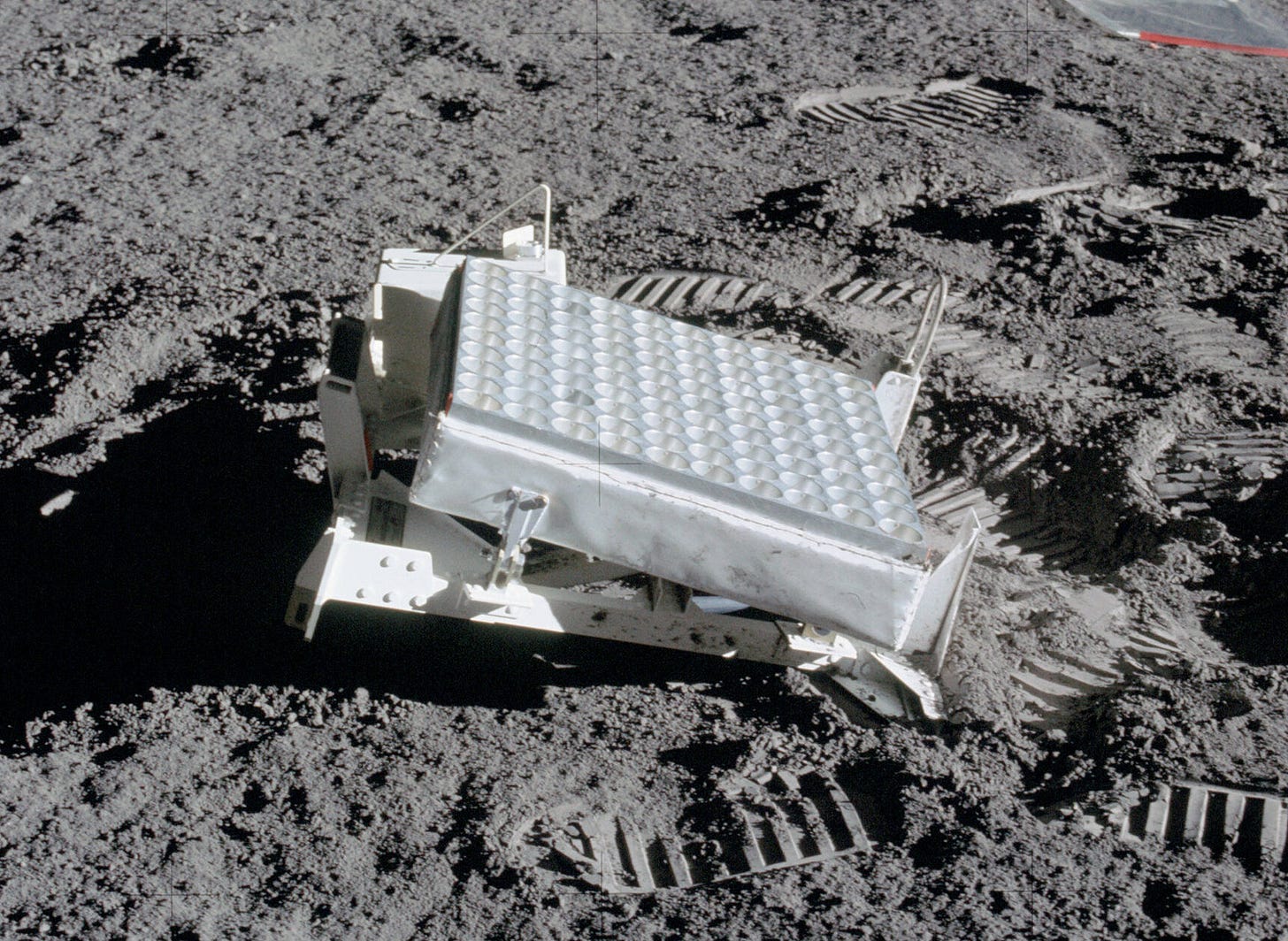

They are also a reason why I’m firm believer that man did land on the moon. One of the pieces of equipment that was left on the moon, first by Apollo 11 on 21 July 1969 is a large retroreflector. There are currently 6 of them on the moon with latest called Vikram and was part of Chandrayaan-3 mission from Indian Space Research Organization in 2023.

The Lunar retroreflector is used to bounce back laser beam sent from Earth to accurately measure Moons distance. How it’s done was even showcased in Season 3, episode 23 of The Big Bang Theory.

USC Viterbi School of Engineering has an excellent primer about the science of it but TL;DR is that there are two different shapes that reflect light back to the source regardless of its orientation, with an optional third which is way more complicated and requires math.

Another good read, a short one, on A brief history of retroreflective sign face sheet materials was done by John Lloyd in 2008.

One is glass beads, based on the effect of the Cat’s eye, often used as an additive (mixed in together with paint) to road signs making them more visible at night. The reflection is not as bright as a prism as it depends on the reflective properties of the underlying paint.

and the other is a negative imprint or arraignment of front silvered mirrors of a specific shape of prism. The orientation of reflective surfaces is setup so that after reflection the beam is returned to the sender with a slight offset. The picture bellow illustrates how two different light rays from different directions are reflected back.

Now, I’m very interested in how they are produced, especially for foil type of retroreflectors.

Larger retroreflectors can be easily made from front silvered mirrors placed in a prism configuration but there is little to no information about how foil-based retroreflectors are made.

“Cat’s Eye” retroreflectors can be molded with standard injection mold techniques.

The manufacture of foil is much more elusive. The only description and information I found was published in The International Society for Optical Engineering, March 2008 which states:

For the microfabrication of 3D - embossing forms a 3-dimensional data rip controls and synchronizes the motions of the axes and the modulation of the laser. The material is ablated subsequently layer for layer by applying an image setter process for each layer with e.g. 5 - 10 µm feed forward resolution. The final depth of the structures is in the range of about 1000 µm. The touchless laser tool allows for free and precise micromanufacturing of each layer. The production time per layer of about 0.2 – 0.6 m2 /h at this high resolution is appropriate to efficient production.

The first Patent for actual production was filed on Sep. 20, 1979, by American Rowland brothers. The patent details how “molding of tiny high accuracy and high definition cube-corners, only 0.15mm to 0.25mm across” was done and “for the first time the highly reflective prismatic optic could be incorporated into a very thin gauge sheet of flexible transparent plastic material such as vinyl or polyester”.1

This means that those highly detailed microstructures were carved into plates, later rollers, heated, and pressed onto a foil substrate. The patent document describes that process and has not changed much except that plates were replaced by more practical rollers and process of making them are now done by lasers. While I could not find how they made the initial pattern I could see high-precision mils with a Pentagram setup being used or even some sort of chemical etching.

You can play with retroreflectors on Ray Optics Simulation website. A direct link is here.

I’m constantly surprised at how everyday objects look like magic if you don’t understand them. They defy the laws of reality but become mundane when explained. It takes a little bit of mystery out of the world but I think it just adds to the awe that it human beings and our ability to figure shit out in most unusual ways.

https://www.rema.org.uk/pub/pdf/history-retroreflective-materials.pdf